Topic

Conductive materials from FCE to ground buildings and warm up roads

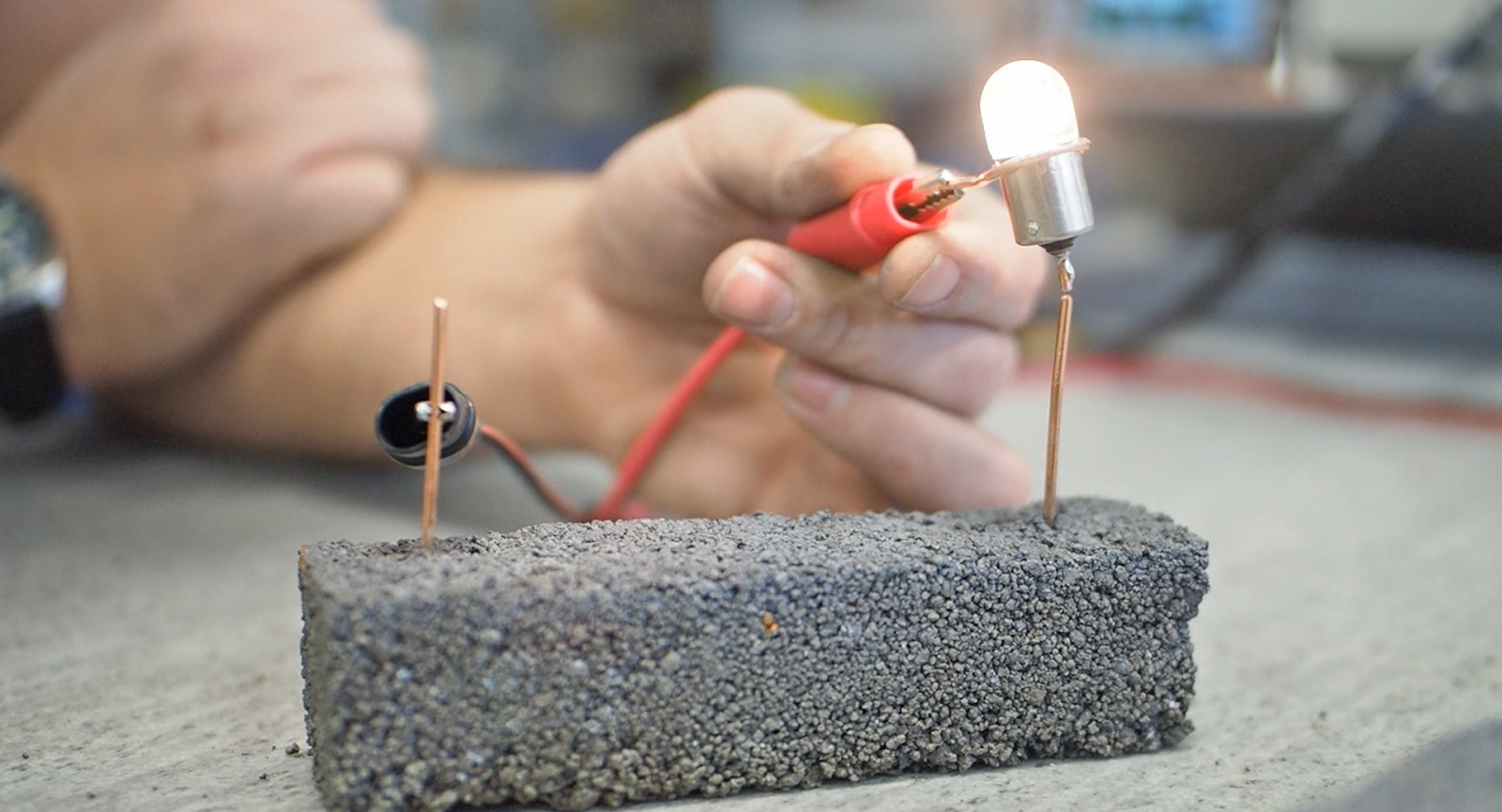

Concrete with a carbon admixture that can conduct electricity and heat. This could be a simplified description of the principle of five new grounding materials developed and tested by a team of researchers from the FCE BUT Institute of Building Materials and Components Technology. New silicate materials can prevent electrical surges in building structures, improve the earthing of railway networks and warm up roads or pavements.

Conductive silicate materials are similar to concrete or mortar – they are a mixture of cement, aggregate, water and carbon that makes it conductive. However, their properties are not well studied and therefore they are rarely used in construction. “For a year and a half, we have been testing what types, nature and distribution of carbon particles are most suitable for achieving good electrical conductivity and maintaining mechanical properties,” explains Šimon Baránek, a PhD student at FCE BUT.

The new materials can replace the traditional lightning rods and ground the buildings. However, they are also used for earthing of high voltage electrical networks – i.e. in the infrastructure of railways, trams, transmitters or optical networks. In these locations, moisture-driven stray currents often occur, which are nowadays directed underground using steel rods.

“However, maintenance of these reinforcements is costly because these currents carry ions away from metallic materials. The higher the voltage, the faster the corrosion. Up to 1 cm of iron can corrode annually. Therefore, the steel earth wires must be replaced frequently,” adds the PhD student. Electrical stray currents have the same destructive effect on pipelines, including gas pipelines.

However, new silicate materials can spread the current and partially replace the earth wires. With their help, stray currents can be directed much deeper, significantly reducing network maintenance costs. Baránek estimates their durability at 20 years. “It is an entirely different way of handling the current. A 20-centimetre bore is made in the ground, into which our material is poured to create a concrete earth wire,” describes the PhD student.

In addition to electricity, silicate materials can also conduct heat and thus serve as heating elements. The FCE research team is now building on previous research in a TACR project and developing silicate building composites with the ability to autonomously control heating. In winter, the technology can be used to heat roads or bus stops.

“Silicate materials can be used to create, for example, bridge plates to which solar panels and a control unit can be attached. Based on the weather forecast, temperature and humidity measurements, the autonomous system adjusts how much electricity flows to the plate. The material starts to heat up and ice formation is prevented,” explains Baránek, outlining how the new material can increase the longevity of roads, eliminating the need for chemical de-icing.

FCE researchers will now test the ability of silicate materials to shield harmful electromagnetic radiation. “Nowadays, metal sheets are used to eliminate signals in rooms, but their disadvantage is their high cost. New silicate materials are cheaper and could become part of plasters and coatings in the future. They can be used in operating theatres or households – for example in bedrooms, where they will completely block the phone and Wi-Fi network. This will create a more pleasant and healthier living environment,” hints Baránek at another application of the building technology from the FCE.

(mar)

The weakest dies, the rest continues to grow

Green facades improve the air and lower the temperature in hot cities

Modern civil engineering will design pleasant shopping centres and optimal escape routes for people

Unique solution to rid houses of mould. Now patented

BUT experts address climate challenges, floods, and the future of Czech water