Topic

Bone tissue carriers from 3D printer make bone regeneration more effective. Their formulations are being tested at FCH BUT

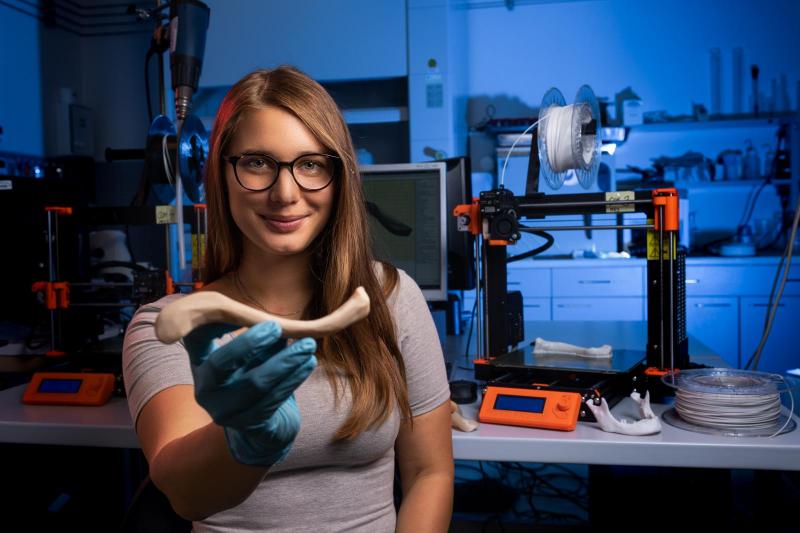

Bone healing after tumours, for example, could in future be made possible by tissue carriers made of biopolymers created by 3D printing. Researchers from the Institute of Materials Chemistry at the BUT have been testing formulations of polymer blends for the fourth year. The basis is the biopolymer poly-3-hydroxybutyrate, for which the faculty obtained a patent in 2013. The material is biodegradable and biocompatible – it is very well suited for medical applications.

Poly-3-hydroxybutyrate (PHB) is a natural polymer formed by bacterial fermentation. Wider use of the material discovered in the 1920s was hampered by the high cost of production. In 2013, however, a patent was created at the FCH BUT, which allows the production of a polymer from waste oils.

"You use something that is so dirty that you couldn't even make bio diesel from it. However, it is food for bacteria, which makes it a valuable material. It's not just recycling, but valorisation and upcycling," explains Veronika Melčová from the polymer group at the FCH BUT, who is researching the application of the material in regenerative medicine.

Because of its hardness, PHB may find use as a temporary bone substitute. Using 3D printing, the researchers use it to produce special tissue carriers, or scaffolds, that act as temporary mechanical support and provide a suitable environment for stem cell growth. For this to happen, the scaffold must be as similar as possible to the tissue being replaced.

Bone tissue – for example, compared to cartilage – has the ability to regenerate well. "If a tumour has to be cut out of the bone, or if any defect larger than 2 centimetres is created, the bone can no longer cope on its own. Although the doctor will screw it in to keep it from moving and fusing, it usually won't grow back at the right thickness. Patients are then in pain or at risk of fracture. That's why scaffolds are added to the area to provide temporary support and stay in place until the bone grows back,” explains the researcher.

The tissue carrier must have suitable surface properties, as each cell type prefers a different environment. "While bone cells like a rough surface, cartilage cells prefer a smooth surface. Additionally, bone has a distinct cancellous structure inside, which we aim to mimic through 3D printing," emphasises Melčová.

Scaffolds made from PHB have the ability to fully degrade in the body. The surrounding tissue absorbs them within a few months without the need for surgical intervention. This is a significant advantage in bone engineering. The degradation of the material must, therefore, occur at the same rate as bone growth.

For five years, researchers from the polymer group have been developing and testing PHB-based formulations suitable for printing bone scaffolds. "We now have several mixtures that exhibit a positive cellular response. We are able to optimise the entire complex 3D printing process, including the preparation of 3D printing filament. We measure surface and mechanical properties, and the created scaffolds are sent to the Institute of Experimental Medicine of the CAS in Prague for in vitro cell tests."

A new method of 3D printing polymer carriers could be not only cost-effective but also straightforward for doctors. “It would be enough to obtain a CT scan and export an image of a specific bone part. It would be uploaded into software that converts it into layers. A doctor could then serially print up to 10 bones on one printing bed," Melčová explains. The same principle is now applied in 3D printing of metals for joint replacements.

Researchers from the polymer group are currently studying the biodegradation behaviour of polymers – how long individual mixtures can be fully absorbed in the body. Mere breakdown of the scaffold in the body is not sufficient. At the same time, it must not provoke an inflammatory response in the body or locally acidify it. "Currently we are looking at a timeframe of months. It depends not only on the specific formulation, but also on the porosity of the specific carrier," says Melčová.

Apart from medicine, the biodegradable polymer from FCH BUT also finds applications in cosmetics, agriculture and packaging materials.

(mar)

Stevan Gavranović studies environmentally friendly lead-free halide perovskites

ARGO underwater: Prototype of student submarine on display at IDET Fair

What do science and juggling have in common? Both require patience, says Vojtěch Jašek, who focuses on research in chemical recycling

Why does the Greenland shark live to be 400 years old? Scientists from FCH BUT want to discover the longevity gene

Challenge as a lifestyle: strojLAB connects students and fields of study across BUT