Ideas and discoveries

Innovative composite from TRICERA ensures lower weight of safes or higher resistance of police shields

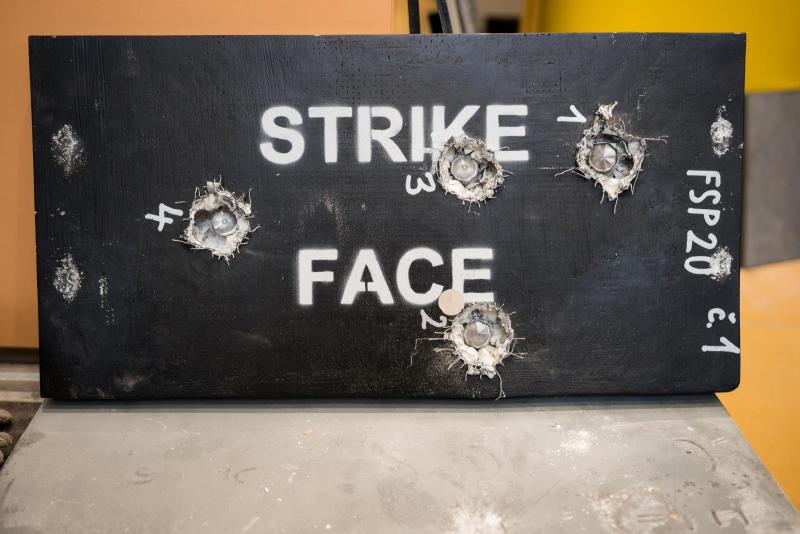

Martin Kachlík and Jakub Roleček, scientists from CEITEC (Central European Institute of Technology) BUT (Brno University of Technology), have been working on the development of ceramic armour for almost ten years. They have come up with a solution in the form of a solid combination of non-porous ceramics and aluminium alloys that is unrivalled in the world. The resulting composite is outstanding in terms of fire resistance, high mechanical resistance and unlimited lifetime. It is a ballistic resistant material that can protect military vehicles or police officers behind mobile shields from firearms or explosives. Scientists in the field of safe construction have found a new opportunity for it. In 2021, they moved some of the research under the umbrella of the university spin-off, now start-up, TriCera.

Many armour manufacturers rely on a combination of ceramic and polymer matrix or offer steel armour. The polymer version is the most common type of armour due to its light weight. However, it has low temperature and mechanical resistance and does not have a long lifetime. Steel armour is very heavy and makes mobility of people and vehicles difficult. “We took a path between the two existing solutions. We wanted to combine ceramics with something that would have more lifetime and especially temperature resistance. So we basically replaced the polymer adhesive in the ballistic-resistant composite with an aluminium alloy,” Kachlík describes the initial experiments. The molten metal, however, does not wet the ceramic and so does not form a strong bond with it. It behaves much like mercury from a broken thermometer, which breaks up into disconnected globules on a flat floor. The tested armour made of this material looked fine at first glance, but due to the incoherence of the ceramic bodies with the matrix, it stopped being effective after the first shot.

Martin Kachlík and his colleagues are currently working on the project “Advanced Ballistic Shields for Personal Protection“, on which they are cooperating with the Police of the Czech Republic. The goal is a mobile ballistic shield for special forces that would also have high resistance. It should also withstand situations after which the ceramic-polymer shields currently in use are discarded: “When a police officer needs to throw a shield down stairs or use it as a ladder for tactical reasons, the manufacturers can no longer guarantee its ballistic resistance,” Kachlík explains. With a new and more resistant model with ceramic-metal armour, the police could use the shield repeatedly for a wider range of threats.

Two years ago, researchers founded a spin-off TriCera, which started to participate in research activities that could not be carried out within the university or only with great difficulty. The spin-off was intended to help offer the developed technologies into practice as quickly as possible. Initially, it seemed that the greatest interest would be in military applications of the new materials. But with the war in Ukraine, the situation has changed.

There is another difficulty related to the above. If military development is slowing down, then it is very difficult for a small company like TriCera to offer incremental innovations for existing solutions: “It is necessary to work together on the development of a combat vehicle right from the start. Manufacturers have to go through very exacting testing, not just ballistic resistance, and if they change just one screw, they basically have to go through it all over again. Using a new material for an existing solution is thus at a significant disadvantage for the combat vehicle manufacturer.”

Scientists from CEITEC BUT are among the world leaders in the field of ceramic-metal armour. No one else produces their certified solution. However, it needs to be promoted more intensively, especially in B2B (business to business) communication. Participation in trade fairs such as the Brno International Defence and Security Technologies Fair – IDET should also help. TriCera will present armour for armoured vehicles or police shields as well as a demonstration of a possible solution for safes.

The results achieved by Martin Kachlík and Jakub Roleček are proof of high level of materials engineeringbut also the diversity of research at BUT. “I have a degree in materials engineering, so that's what I'm most passionate about. I try to find the best solution for the application. It's part physics, part chemistry, and although many don't think so, it's also largely design and manufacturing technology. Success is led by a diverse team, where you can approach problems from different angles and say that an idea is good in three ways, for example, but needs to be redesigned for the fourth.” Martin Kachlík gives an insight into the workings of the research team.

(kub)

Who is Martin Pumera, one of the most cited scientists in the world?

Researcher Jakub Lázňovský is developing software for objective evaluation of vertebral fusion success

3D cartilage atlas of mid-trimester human embryos

Villain or Hero? The Electron Microscope as a Detective

A priceless offer. CEITEC will help researchers to bring the results of their work to the market