Ideas and discoveries

Research from FCH BUT has contributed to a better understanding of cement-free concrete. The finding were also published in prestigious journals

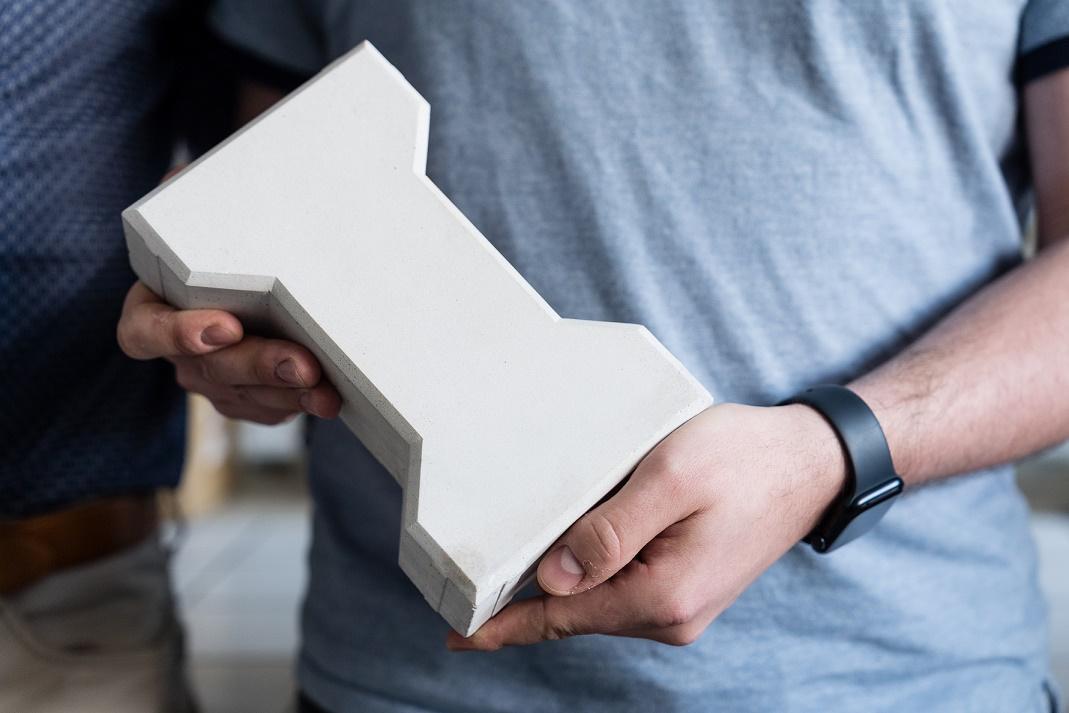

Alkali-activated materials have long been dealt with at the Institute of Materials Chemistry, Faculty of Chemistry, BUT, thanks to national and international basic and applied research projects. “It is mostly seen as an alternative to Portland cement-based materials, especially for applications requiring high chemical resistance or resistance to high temperatures. Furthermore, the main advantages include that alkaline-activated materials are more environmentally friendly and sustainable in production. Especially because it is produced from industrial waste and secondary products. So we don't waste natural resources like limestone. It is the main raw material for cement production, and in addition, its decomposition produces carbon dioxide,” Vlastimil Bílek lists the benefits.

One of the major problems with these materials, however, is that they do not contain the common organic admixtures used in traditional concrete. “Conventional additives, such as superplasticizers, which even a small dose will significantly thicken the concrete, are designed for conventional cement. Thanks to them, we can add less water and get more strength and durability. Concrete can also be used to build complex massive structures such as skyscrapers or bridges. However, these plasticizers usually do not work with alkaline-activated materials. We wanted to get deeper into which substances work, which don't, and why,” explains Lukáš Kalina, about the aim of their three-year project under the auspices of the Grant Agency of the Czech Republic.

However, according to Vlastimil Bílek, there are already interesting applications in the world. “In Brisbane, Australia, for example, an airport runway is made of alkali-activated slag and fly ash. In our country, commercial use is much smaller,” he says, adding that European legislation in particular prevents more widespread use. “Concrete standards do not foresee the complete absence of Portland cement as a binder,” he adds. Architects and designers, who have more confidence in cement, are also cautious, according to him. “But standardisation and testing is already being worked on globally,” Bílek points out.

They themselves plan to continue the research and possible application. “To some extent, we are already following up this project with another one, primarily at the Faculty of Civil Engineering of the BUT. We have also been approached by a company that would like to work with us on the production of alkali-activated parts. I don't want to be completely specific yet, but it looks promising,” says Lukáš Kalina, adding that greater industrial production is their ultimate goal. “We can research and test something here in the laboratory, but if it doesn't make it into practice, it's half the point,” Vlastimil Bílek concludes.

(zeh)

They were looking for a way how to supress the negative effect of zinc on cement. They developed a material with even better properties

We can improve the quality of life of the whole population, says Ivana Márová

Nilmore's circular clothing allows you to use the fibre repeatedly

Experiment from FCH BUT shows that bioplastics are not always the greener choice

Stevan Gavranović studies environmentally friendly lead-free halide perovskites