Ideas and discoveries

Ballistic panel from FCH to increase security of critical infrastructure in the Czech republic

Researchers from the FCH (Faculty of Chemistry) BUT (Brno University of Technology) in cooperation with experts from Bogges have come up with a mobile solution for the protection of critical infrastructure objects. Through successive projects and improvements based on testing, they have developed the Ballistic Protection Panel (BPP), which, compared to the alternative of monolithic concrete walls, is more resistant to firearms and can be installed by human power without the use of heavy handling equipment. Compared to steel armouring, it is significantly cheaper.

Today we are more threatened by hybrid or paramilitary attacks similar to the one behind the explosion of the ammunition depot in Vrbětice than by an armed army armed to the teeth. Attacks can take the form of sabotage or terrorist attacks, often on critical infrastructure. The Czech Republic should have a rapid and mobile response to this new type of threat.

“The existing protection of buildings has mostly meant the installation of concrete road barriers in front of the entrances, or a permanent high-strength reinforced concrete monolith has been created at the building. However, the critical infrastructure of this republic, such as waterworks, gas plants or electricity substations, is not effectively protected against a possible hybrid attack and the subsequent intrusion of attackers,” comments František Šoukal from FCH, who deals with the issue of ballistic protection and is part of the team of experts behind the special concrete innovation.

The idea came from the doctoral thesis Ballistic Resistant Concretes by Ondřej Koutný, who now works for Bogges. The work opened the topic of the development of a material based on Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC) with increased ballistic resistance, together with the question of methodology for formulation design and testing.

This was followed by the development of a material for BPP that at first glance resembles conventional concrete but contains a number of specific, albeit commercially available, ingredients. The main binder is a special cement. The binder also includes microsilics, a by-product of the production of a metal silicon on chips, which has a particle size below 1 µm and fills the spaces between the cement. The mixture also contains water and very fine aggregates. The combination of superplasticizers is very important for the final strength of the material, as they generally allow to achieve the lowest possible water content in the mixture while maintaining fluidity. For the right result, the mixture is finally mixed and stored in a special way.

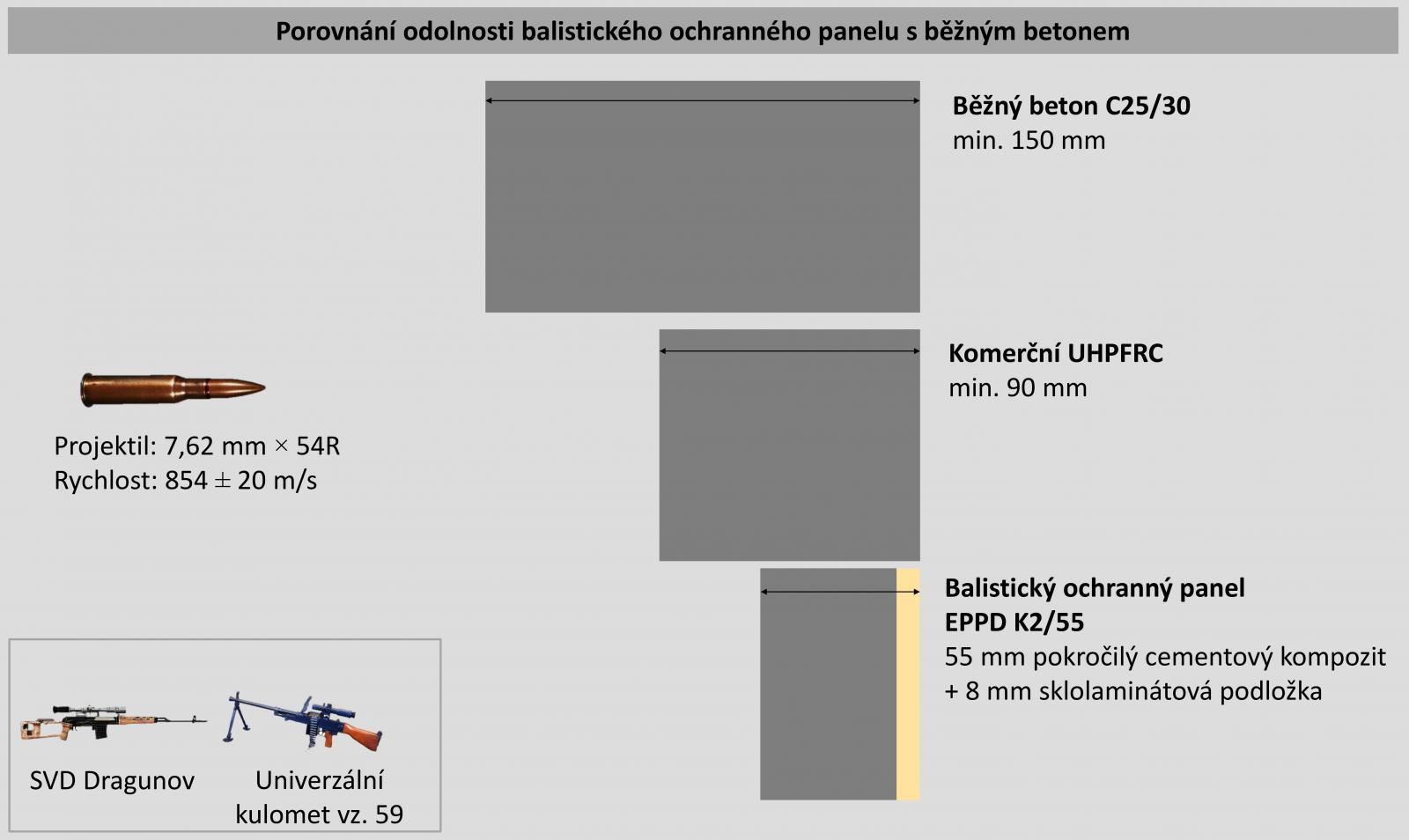

In the next phase, the researchers determined the bulk weight and workability of the material and performed static tests for compressive and flexural strength. After the samples were cast, the tests moved to Prototypa's three ballistics laboratories (tunnels) near the FCH, where the samples were shot and then their behaviour was evaluated. As a result of the measurements, for example, using a strain gauge, and subsequent calculations, it was determined what thickness of panel would still prevent a puncture. The 55 mm thick BPP is thus able to withstand multiple shelling from firearms with standard and armour-piercing projectiles up to 7.62 mm calibre and thus meet the NATO A3 standard. “I can't imagine a similar application of conventional concrete that would have comparable resistance to the Ballistic Protection Panel and still be relocatable without mechanization. We are talking about 5 cm of panel replacing more than 15 cm of normal concrete of class C 25/30.” Šoukal describes the main advantages of BPP.

The culmination of long-term research work is the project “Means for Increasing Ballistic Protection of Vehicles and Critical Infrastructure“, which is currently in its final phase, where researchers are succeeding in further advancing the possibilities of using BPP. Researchers are developing entire walls made of manually manipulated panels that can temporarily or permanently protect, for example, the entrance of government institutions or critical infrastructure sites.

Layering walls offers interesting possibilities: “We have now developed a system to NATO A4 resistance class that protects against the 12.7 mm armour-piercing projectile used, for example, in armoured vehicle machine guns.” František Šoukal describes. The researchers achieved this by placing two walls of BPP behind each other. In addition, the projectile is deflected from its path by an air gap between the walls, which can be filled with ordinary aggregate for greater efficiency.

In the future, the researchers are planning, for example, a BPP suspension system for facades or a project for shielding against indirect hits from mortar or artillery shells. Few people know that shrapnel from the explosion of these weapons has up to twice the impact velocity of projectiles from firearms. Ballistic panels will thus have to withstand an even significantly greater destructive force than before.

“Our advantage is that we can make BPP with extremely good parameters even from relatively ordinary aggregates. We don't need high-strength aggregate, which is very expensive, and yet we are getting high strength and ballistic resistance values,” says Šoukal, referring to an important motivation for scientists in developing BPP, which is to optimise costs while maintaining high resistance. Since the other components of the mixture do not come from laboratory research and are commonly available on the market, the researchers managed to reduce the price of BPP to an acceptable level of about CZK 25,000 per m³. The UHPFRC category, to which the BPP material belongs, is priced up to CZK 100,000 per m³. Also, compared to armour-plated rolled steel, BPP is about three times cheaper for the same area weight and ballistic resistance.

The FCH researchers now want to start offering the product commercially together with Bogges. A suitable opportunity is, for example, the International Defence and Security Technologies Fair – IDET in Brno. Potential bidders for BPP could be state units – especially the Czech Army, the Ministry of Interior and operators of critical infrastructure objects. A Czech private company engaged in the construction of civil defence facilities in family houses has also shown interest in the system, which is now in great demand.

“There is a need to protect critical infrastructure, which is why we came up with this innovation. Also in view of the security crisis in Ukraine, the state should be prepared to temporarily increase the protection of its important facilities. If the state wants to use this mobile protection on the basis of the study, then it would be advisable to create a stockpile, because in case of a crisis it will not be possible to produce sufficient quantities of BPP in time.” concludes František Šoukal from the Faculty of Chemistry of the BUT.

In high school, she devoted herself to making cosmetics. She has now come second in the business competition and she is preparing new products

From Munich to Brno by bike: Interview with double degree student Jana

Cheaper, better quality and eco-friendly. FCH BUT researchers create new dextrin adhesive

PhD student Veronika Řeháková on bioplastics research in Malaysia: If you put your best into science, it will bear tasty fruit

Nilmore's circular clothing allows you to use the fibre repeatedly